Industry Knowledge Expansion

Defining Oil-Free MEWPs:

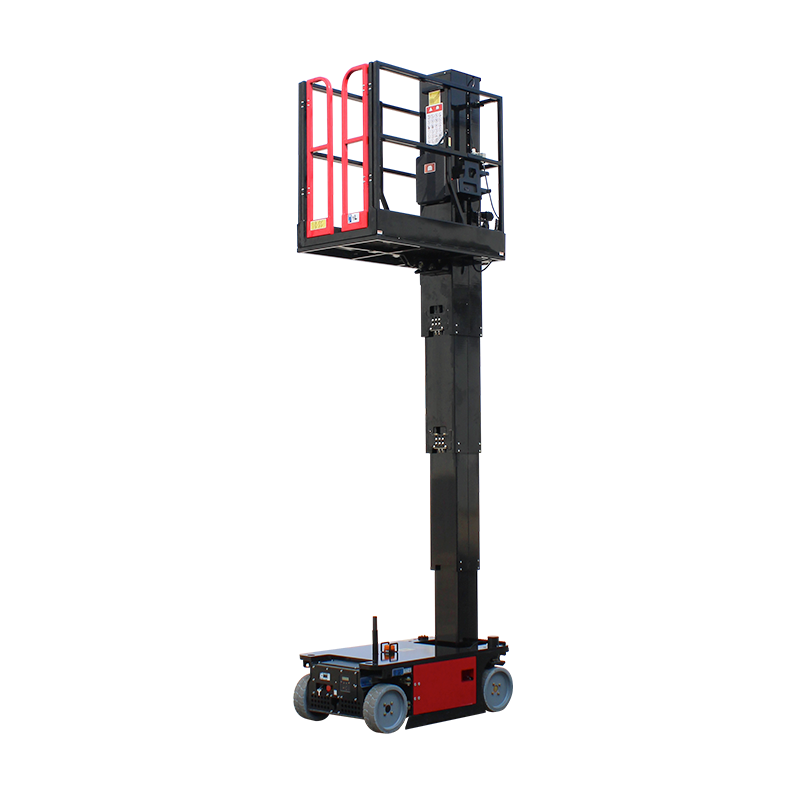

The introduction of oil-free Mobile Elevating Work Platforms (MEWPs), also known as Aerial Work Platforms (AWPs), powered entirely by electricity, marks a significant leap towards environmentally conscious and efficient aerial access solutions.

Oil-free MEWPs represent a groundbreaking advancement in aerial access technology. Unlike traditional MEWPs that rely on hydraulic systems using hydraulic oil, oil-free MEWPs utilize electric systems for propulsion, elevation, and articulation. This shift eliminates the need for hydraulic oil, reducing environmental impact and simplifying maintenance.

Benefits of Oil-Free MEWPs:

The adoption of oil-free MEWPs offers numerous advantages, both in terms of environmental stewardship and operational efficiency:

a. Environmental Sustainability: By eliminating hydraulic oil, oil-free MEWPs significantly reduce the risk of oil leaks, spills, and contamination. This directly contributes to protecting soil, water sources, and the overall ecosystem.

b. Zero Emissions: Oil-free MEWPs are powered entirely by electricity, resulting in zero emissions during operation. This aligns with efforts to reduce air pollution and combat climate change.

c. Quieter Operation: Electric propulsion systems produce significantly lower noise levels compared to traditional hydraulic systems, creating a quieter and less disruptive work environment.

d. Simplified Maintenance: The absence of hydraulic components reduces the complexity of maintenance. Operators benefit from fewer components that require servicing, resulting in decreased downtime and maintenance costs.

e. Lower Operating Costs: Electric power is often more cost-effective than hydraulic systems, contributing to reduced operating expenses over the lifespan of the equipment.

Applications of Oil-Free MEWPs:

Oil-free MEWPs find applications in various industries and scenarios:

a. Urban Areas: The quiet and emission-free operation of oil-free MEWPs makes them well-suited for use in urban environments, minimizing noise pollution and air quality concerns.

b. Indoor Work: Oil-free MEWPs are ideal for indoor tasks such as maintenance, installation, and repairs in warehouses, factories, shopping malls, and event venues.

c. Sensitive Environments: Construction and maintenance projects in environmentally sensitive areas can benefit from oil-free MEWPs, as they minimize the risk of oil contamination.

Español

Español