Industry Knowledge Expansion

What safety protection measures are there for vertical lifts?

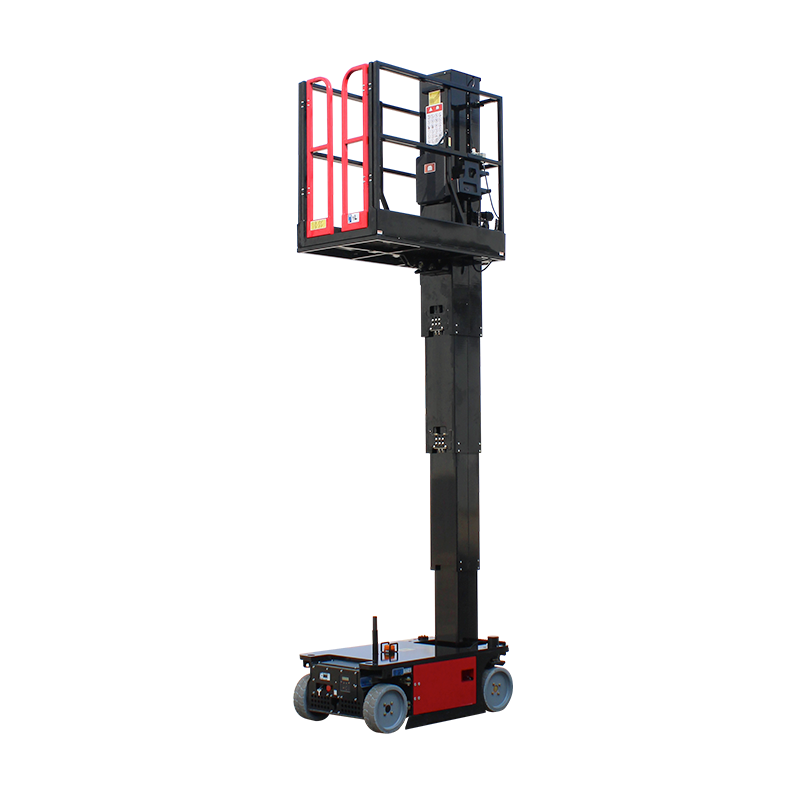

In modern industrial environments, equipment safety is a key factor in ensuring production efficiency and personnel safety. REES Industries' Vertical Lifts use multiple safety designs to ensure stability and efficiency during operation.

Mechanical safety devices

REES Industries' Vertical Lifts are equipped with a series of sophisticated mechanical safety devices to minimize operational risks. The design of limit switches is particularly critical. These switches are accurately installed on the top and bottom of the container and can monitor the position information of the container in real time. When the container approaches or exceeds the set travel range, the limit switch will be triggered quickly to immediately stop the movement of the container, thereby effectively preventing collisions or exceeding the design limits.

In an emergency, the emergency stop buttons set around the equipment enable operators to respond quickly. Whenever these buttons are pressed, the system will quickly cut off the power supply to ensure that the equipment stops running immediately. This design not only improves operational safety, but also provides the necessary protection for operators.

In addition, the application of buffers cannot be ignored. It is installed at the end of the container's running path, which can effectively absorb the kinetic energy generated by the container's movement, significantly reduce the impact force, protect the equipment and cargo from damage, and ensure the long-term stability of the equipment under high-frequency use.

Electrical control system safety

REES Industries also excels in the safety design of the electrical control system. The overload protection device monitors the motor current in real time. Once an abnormal current is found, the system will immediately shut down to prevent the motor from being damaged due to overheating. This design not only protects the motor itself, but also ensures the stable operation of the entire electrical system.

In the event of a power outage, the power-off protection device will automatically lock the system to prevent the container from falling freely, ensuring the safety of operators and cargo. This design enhances the safety of the equipment in emergencies and avoids possible serious consequences.

In addition, the key components and control signals of Vertical Lifts are all redundantly designed. This design concept significantly improves the reliability of the system. Even if a component or signal fails, the system can still operate normally, ensuring the safety and continuity of operation.

Software safety function

REES Industries' Vertical Lifts also integrates advanced software safety functions to further enhance the safety of the equipment. The anti-collision system monitors the surrounding environment of the equipment in real time through high-precision sensors. If a potential collision risk is detected, the system will stop operating immediately to avoid accidents.

The equipment self-check function is another important safety measure. This function can automatically detect the operating status and abnormal conditions of the equipment. If any abnormality is found, the system will quickly issue an alarm and stop the equipment operation to ensure that the operator can deal with potential safety hazards in time.

The permission management function is controlled by software to ensure that only authorized personnel can operate or change system settings. This design effectively prevents unauthorized operations and reduces the safety risks caused by misoperation or malicious operations.

Physical protection measures

In terms of physical protection, REES Industries' Vertical Lifts also show excellent safety design. The combination of safety doors and safety light curtains ensures that the system is allowed to operate only when the safety doors are closed and the light curtains are not blocked. This design effectively prevents operators or goods from accidentally entering the dangerous area during the operation of the equipment, thereby improving the overall operational safety.

What are the safety regulations for vertical lifts when operating?

In modern industrial environments, the safe operation of Vertical Lifts is essential. To ensure the efficient operation of the equipment and the safety of the operators, Reeslift Ltd. has formulated a series of strict operating specifications and safety guidelines, covering equipment inspection, operator qualifications, dress requirements and operating procedures.

Pre-operation inspection

Before using the Vertical Lifts each time, the operator should conduct a comprehensive equipment inspection to ensure that it is in the best working condition. The inspection content includes but is not limited to whether the controller, instrument and safety switch function properly, and whether there are damage or defects in key components such as protective covers, fuses, suspension wheels and motion wheels. In addition, the operating status of the electrical system and safety system should also be carefully checked to ensure that there are no faults or abnormal conditions. The Vertical Lifts designed by Reeslift Ltd. are equipped with an advanced self-checking system that can automatically detect the status of key components before each start-up, providing operators with instant equipment status feedback, thereby effectively reducing operational risks.

Operator qualifications

Only operators who have received professional training and obtained the corresponding qualifications can operate Vertical Lifts. All operators must receive comprehensive safety operating procedures training before taking up their posts and be familiar with equipment performance, operating procedures and potential risks.

Clothing and protection

When operating, operators must wear clothing and safety shoes that meet safety standards, and avoid wearing loose clothing, trousers and slippers that may affect operation or bring safety hazards. According to specific operation requirements, operators are also required to wear personal protective equipment such as safety helmets, safety belts and protective glasses. Reeslift Ltd.'s Vertical Lifts are designed with full consideration of the safety needs of operators and are equipped with complete safety protection facilities, such as safety doors, safety light curtains, etc., to ensure the safety of operators during operation.

Operation process specifications

During operation, operators must strictly follow the instructions and operating manuals and implement safe operating procedures. During lifting and lowering, operators should stay focused, avoid violent swinging and jumping, and never perform rotational movements. When transporting personnel, ensure that all personnel's safety belts and protective devices are worn correctly to ensure their safety. In addition, it is strictly forbidden to overload on Vertical Lifts. Operators must be familiar with the load limits, including the total weight of workers and work materials, and operate within the rated range of the equipment to ensure the safety and stability of the equipment.

Español

Español